Features and Pros & Cons

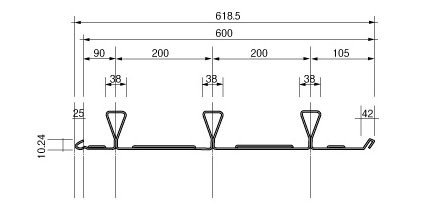

Sectional diagram

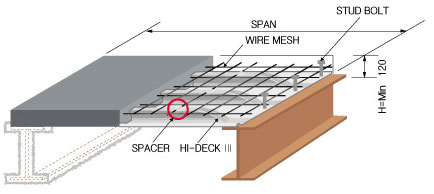

Structural detail

Reduction of construction time

- Reduces construction time compared to existing deck plates because its installation is simplified by using 2 spans continuously and because of dust sleeve reinforcement work, the wiring system, and flexible piping work.

- Since the bottom plate is flat, ceiling finishing work is simple. Additionally, HI-DECK II has outstanding sound- and vibration-proof characteristics. It is ideal for an apartment application which requires flexible spaces.

Safety

- Since an upper triangle-shaped rib is buried in concrete, it serves as a connector between the bottom plate and concrete. When concrete is poured, HI-DECK II holds its shape to form a strong slab able to withstand extreme conditions such as earthquakes or fire.

Economical

- Since the possible thickness varies (0.8mm, Over 1.0mm, Over 1.2mm, Over 1.4mm, Over 1.6mm), HI-DECK II offers some economic benefits. The flat bottom reduces the bottom of the slab so that it reduces the story height. Therefore, it is ideal for high-rise buildings.

- HI-DECK II can reduce about Under 4.3% of the amount of concrete due to a 10mm camber and a triangle-shaped rib when the thickness of the slab is 12cm. The wire mesh on the upper part of the slab minimizes the use of additional reinforced rods.

Sectional Performance

- HI-DECK II is widely used for both low- and high-rise buildings. It can be used in under- and above-ground applications as well as for building factories and bridges that use reinforced concrete, steel frames, and steel-reinforced concrete. It is especially appropriate for building steel frame skyscrapers.

| Product | Thickness m |

Weight kg/m2 |

Cross-section cm2/m |

Neutral axis cm |

Geometrical moment of inertia cm4/m |

Section modulus | |

|---|---|---|---|---|---|---|---|

| Z+ | Z- | ||||||

| HI-DECKⅡ | 0.8 | 1Under 3.6 | 15.63 | 2.24 | 125.8 | 56.2 | 2Under 3.9 |

| Over 1.0 | 16.7 | 19.24 | 2.25 | 156.3 | 69.5 | 29.8 | |

| Over 1.2 | 19.9 | 22.94 | 2.25 | 186.7 | 82.9 | 35.6 | |

| Over 1.4 | 1Under 3.3 | 26.60 | 2.26 | 217.2 | 96.1 | 4Over 1.5 | |

| Over 1.6 | 26.4 | 30.27 | 2.26 | 247.2 | 109.4 | 47.2 | |

Slab Standard

| Product | Materials | |||

|---|---|---|---|---|

| Deck Plate | Concrete | Wire Mesh | Stud Bolt | |

| HI-DECKⅡ | KSD 3506(Z27) Continuous galvanized sheet SGCO 0.8T SGCO Over 1.0T SGCO Over 1.2T SGCO Over 1.4T SGCO Over 1.6T |

Normal concrete Strength:over 210kgf/cm2 Slab thickness :over 120mm Slump:over 15cm |

KSD 7017:6_100×100 Min. thickness of cover concrete :over 20cm Lap splice length:150mm |

KSD 3752 Carbon steel for machine structural use Φ16 SM 10C SM 20C |

Fireproof Construction

| Product | Plate thickness mm |

Distance between beams m |

Concrete thickness mm |

Load kgf/m2 |

Fireproof performance | |

|---|---|---|---|---|---|---|

| HI-DECKⅡ | A | Over 1.0 | Under 3.2 | Over 120 | Under 1300 | 2 hours |

| B | Over 1.0 | Under 3.2 | Over 135 | Under 950 | 2 hours | |

| D | Over 1.2 | Under 3.6 | Over 135 | Under 850 | 2 hours | |

| O | Over 1.0 | Under 2.9 | Over 150 | Under 1,600 | 2 hours | |

| P | Over 1.2 | Under 3.4 | Over 150 | Under 1,100 | 2 hours | |

| Q | Over 1.6 | Under 4.05 | Over 150 | Under 1,100 | 2 hours | |

- The above detail must be followed

- oncrete thickness is the thickness of the slab including the deck plate

Max. Span Based on Allowable Load

| Thinckness | SLAB thickness (mm) |

Max. span for construction | Max. span when using the building | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Load(kgf/m2) | ||||||||||||

| 1 | 2 | 300 | 400 | 500 | 600 | 700 | 800 | 900 | 1000 | 1400 | ||

| 0.8 T | 130 | 2872 | 3018 | 3.9 | 3.7 | 3.5 | 3.3 | 3.2 | 3.1 | 3.0 | 2.9 | 2.5 |

| 135 | 2849 | 2993 | 4.0 | 3.8 | 3.6 | 3.5 | 3.2 | 3.2 | 3.1 | 3.0 | 2.6 | |

| 150 | 2782 | 2923 | 4.2 | 4.0 | 3.8 | 3.6 | 3.3 | 3.3 | 3.2 | 3.1 | 2.8 | |

| 1.0 T | 130 | 3080 | 3242 | 4.4 | 4.1 | 3.9 | 3.7 | 3.4 | 3.4 | 3.3 | 3.2 | 2.9 |

| 135 | 3056 | 3215 | 4.5 | 4.2 | 4.0 | 3.9 | 3.6 | 3.6 | 3.4 | 3.3 | 2.9 | |

| 150 | 2985 | 3140 | 4.8 | 4.5 | 4.3 | 4.1 | 3.8 | 3.8 | 3.6 | 3.5 | 3.1 | |

| 1.2 T | 130 | 3262 | 3647 | 4.7 | 4.5 | 4.2 | 4.1 | 3.7 | 3.7 | 3.6 | 3.5 | 3.1 |

| 135 | 3235 | 3617 | 4.8 | 4.6 | 4.3 | 4.2 | 3.8 | 3.8 | 3.7 | 3.6 | 3.2 | |

| 150 | 3160 | 3533 | 4.9 | 4.9 | 4.6 | 4.4 | 4.1 | 4.1 | 3.9 | 3.8 | 3.4 | |

| 1.4 T | 130 | 3423 | 4031 | 4.7 | 4.5 | 4.2 | 4.1 | 3.7 | 3.7 | 3.6 | 3.5 | 3.1 |

| 135 | 3395 | 3999 | 4.8 | 4.6 | 4.3 | 4.2 | 3.8 | 3.8 | 3.7 | 3.6 | 3.2 | |

| 150 | 3317 | 3906 | 4.9 | 4.9 | 4.6 | 4.4 | 4.1 | 4.1 | 3.9 | 3.8 | 3.4 | |

| 1.6 T | 130 | 3566 | 4390 | 4.9 | 4.8 | 4.6 | 4.4 | 4.0 | 4.0 | 3.9 | 3.8 | 3.4 |

| 135 | 3537 | 4355 | 4.9 | 4.9 | 4.7 | 4.5 | 4.2 | 4.2 | 4.0 | 3.9 | 3.5 | |

| 150 | 3456 | 4255 | 4.9 | 4.9 | 4.9 | 4.9 | 4.5 | 4.5 | 4.3 | 4.2 | 3.8 | |

- Finishing material load = 200kgf/m2, construction load = 150kgf/m2

- fck: 210kgf/m2

- Max span is clear span during construction