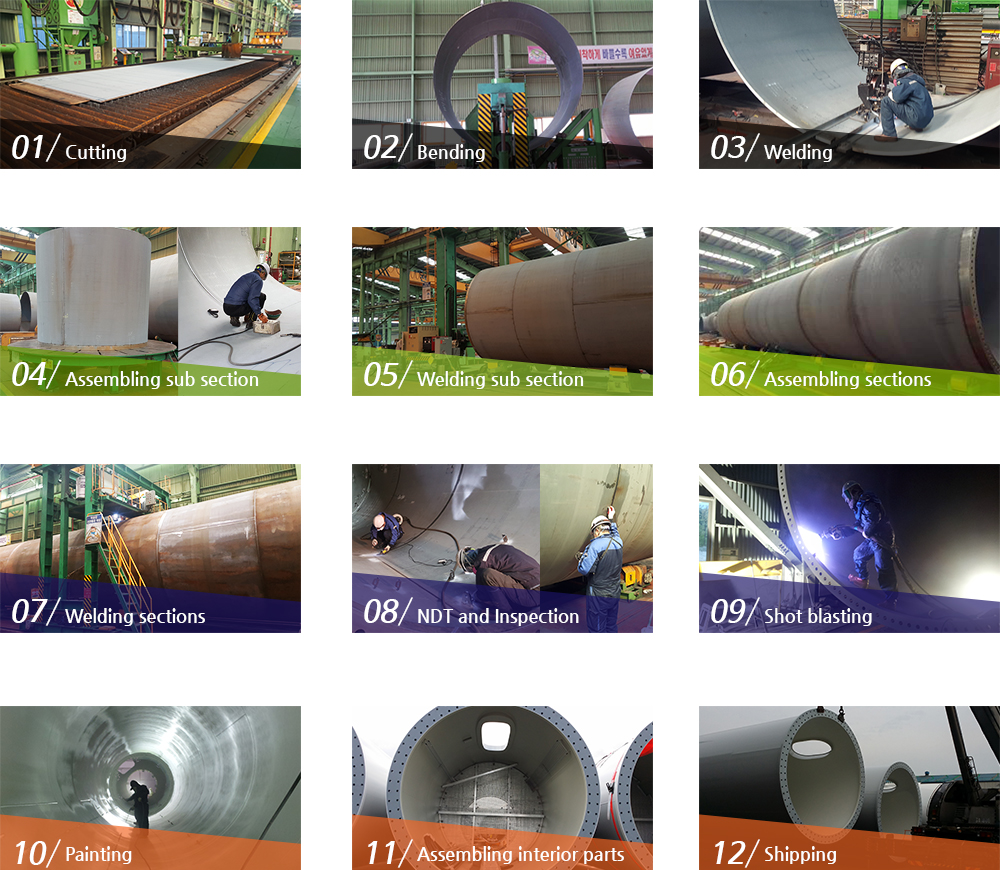

Production Process

Short Pipe Welding Crane

-

MAKER Manjoo Industries roduction capacity 8 cans/day Primary use LONGITUDINAL OUTSIDE WELDING HOISTING PART UP – DOWN METHOD AC Motor 3.7kw * 6P SPEED 2.5m/min STROKE 4,770mm CHAIN RS80(Super heavy load) GUIDE Rollr&Camflower Carrier Part Load 15 ton SPEED 10 m/min POWER 1.5 kw * 4 P 1/90

Fit-up Equipment

-

MAKER Dongyeon roduction capacity 1 section/day Primary use SUB-SECTION, CAN+FLG`, SECTION FIT-UP DOUBLE WORM REDUCER DWBM–155/135 (1/800) CYLINDER CAPA. Φ2,200 ~ Φ4,500, 50 ton CYLINDER ROLLER Φ180 mm CYLINDER STROKE 200 mm

Manipulator

-

MAKER Manjoo Industries roduction capacity 1 SEC’ / 일

Primary use Circumferential In/Outside Welding BOOM HORIZONTAL PART STROKE 7,000 mm SPEED 0.25 ~ 2.4M / Min. POWER SOURCE 220V * 60Hz * 3PH

0.75KW * 4PBOOM HOISTING PART STROKE 4,500mm SPEED 1,200mm / Min. POWER SOURCE 220V * 60Hz * 3PH

1.5KW * 6PROTATION PART ANGLE ± 180˚

Mutil-pipe Welding Crane

-

MAKER Manjoo Industries roduction capacity 1 section/day Primary use Circumferential Outside Welding HOISTING PART SPEED 5,000~10,000 mm/min. MOTOR 1.5KW * 4P 2 RAIL SPAN 5,850 mm RAIL LENGTH 90 m HOISTING PART

UP – DOWN METHOD AC Motor 3.7KW * 6P SPEED 2.5 m/min STROKE 4,500mm CHAIN RS80 (Super heavy load) GUIDE ROLLER & CAMFLOWER

PHOTO / PLANT